The fact that I am going to be running Air Lift Performance components on Project Why Wait shouldn’t come as much of a surprise. The large banner behind my work bench was a bit of foreshadowing, and an easy indication of where my air ride loyalty lies.

I’ve had Air Lift Performance struts, and Autopilot v2 management supporting my car since 2013 and the system has performed admirably all year round in that time.

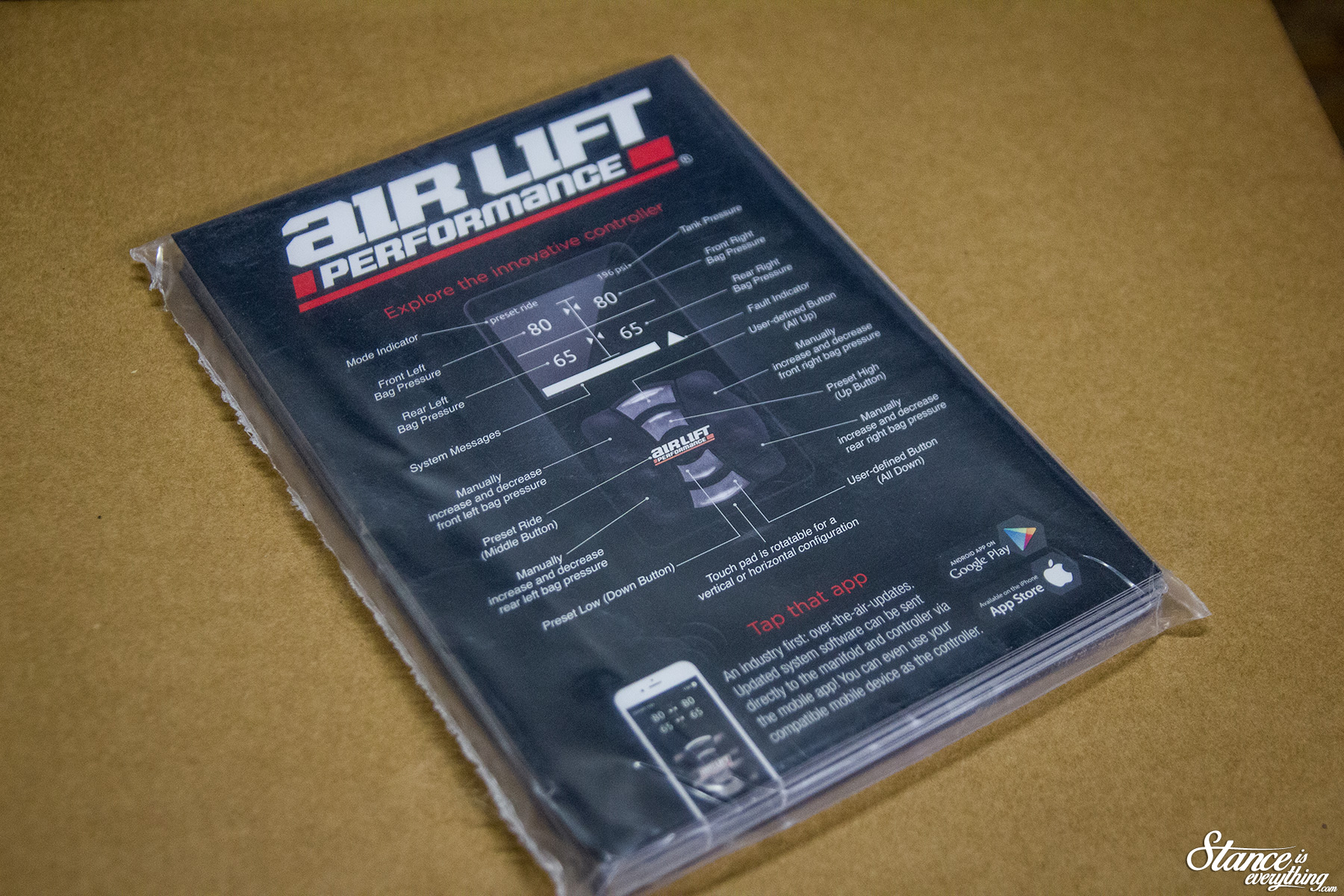

When Air Lift Performance released their new management system it was quite literally the only digital option I considered.

ALP doesn’t release a product just to release a product, nor do they do they rush anything to the market. Their entire line up is calculated and developed to better perform than their previous iterations and market alternatives. The products are only released after rigorous testing. This testing happens both in the lab of their Michigan based facility and on the roads.

Everything you see above actually arrived almost a year ago but I managed to resist the urge to completely un-box the delivery until a few weeks ago.

Since receiving my shipment the 3P/H management has become pretty common place which means I had seen it before.

However one part of the equation I had never seen was the physical packaging.

It might seem silly to talk about the packaging of a product, but when you’re dealing with a wide variety of manufacturers the ones that take time to work on presentation stand out.

Parts such as this cost a significant chunk of change, so it is nice when a company values your purchase by not only standing behind their product, but putting it in a nice package to boot.

Before I got to opening the management however I unwrapped the brawn that goes with the brains.

For the truck I’ve gone with dual 2.5 gallon brushed aluminium tanks, literally twice what is in my Mazda. My reasoning for going with more air is pretty simple, not only is the truck heavier, but the truck also affords more physical space to mount the components than my speed3 does.

More air equals more play time and less compressor noise.

I chose the brushed option, over the polished alternative, because I knew I’d be painting the tank. Poof can, powder, or spray gun it is easier to prep and paint a brushed surface than it is a polished one.

I also know these tanks are pretty stout after the one in my car endured a fairly significant accident without failing.

For compressors I chose a dual pack of black Viair 444c units. This is again double what is in my car. I’ve never had any significant issue with my Viair units, and I have not found them overly loud so I saw no reason to choose something else.

One downside to Viair compressors was that previously they only came in chrome. That has been rectified with their black line, and the black line looks damn good.

The leader hose and check valve are also black which is a nice touch. However if there is a Viair weak link it’s the check valve above which I’ll be replacing with a SMC unit.

Moving back to the 3P/H unit the first box I opened was the manifold and controller. Yes I’d seen both before in person but these were different because these were mine, which meant I could stare, ogle, and fondle at will.

If I had a single criticism of the Autopilot V2 system it would be that the controller is fairly utilitarian. It works flawlessly, is sized well, and is quite rugged, but visually it’s not the most attractive thing in the world. Especially when compared to some of the other options that are available.

This is certainly not the case with the new controller which is a lovely piece of kit. It carries with it the significant weight of a quality piece along with the fit and finish you’d expect with any modern quality electric device.

If I’m to be honest I’ve already got a bit of anxiety about cleaning finger prints off it meticulously, similar to how I was with my first idevice.

The manifold is also a very nice piece. The harness entry point is in a much more becoming location than the V2s plug was located. An engraved plate bearing the Air Lift Performance logo, versus the Air Lift Company Logo of the Auto Pilot V2, looks great as well.

The manifold is also a very nice piece. The harness entry point is in a much more becoming location than the V2s plug was located. An engraved plate bearing the Air Lift Performance logo, versus the Air Lift Company Logo of the Auto Pilot V2, looks great as well.

Overall this is a piece designed to be featured in air installs rather than tucked away out of view.

SMC push to connect fittings are the line interface of choice, and I ordered this one in 3/8 line for faster articulation than with my car. Again the whole ‘it weighs more’ reality plays into the choices here.

From what I’m told a truck on 1/4 is no bueno.

The pressure vs ride height choice was an easy one to make. I like my pressure based system, don’t get me wrong, but since becoming a father and carrying wildly different weight loads of stuff from weekend to weekend I see the value in a height based system.

Stance is, as you know, everything in my eyes and typically I don’t allow for a lot of room for error in my preferred ride height.

Suffice to say too low past my desired pre set and things hit other things which isn’t ideal.

Furthermore since my wife will be driving the truck on occasion the ability to set a (slightly) higher preset for her and not have to worry about what she’s hauling altering the height is a great piece of mind.

The installation of the system, will be documented at a later date but I did take a look at all the weatherproof, tested, harnesses to see what I was in for.  With the included literature I’m sure it should be pretty straight forward. Should it not be Blair has offered to come by and lend a hand in my garage for a beer or two.

With the included literature I’m sure it should be pretty straight forward. Should it not be Blair has offered to come by and lend a hand in my garage for a beer or two.

To make the installation as easy as possible Air Lift Performance includes literally everything you need include a water trap, and even a line cutter.

Now obviously there’s quite ways to go before I get to installing these system, but if you take a peak on instagram you’ll notice that I’m actually not all that far from some of these parts getting put to use in the near future.