Late 2014 both the Taylor’d Customs ’57 Chevrolet 3100 and the ’61 Impala ended up under new ownership, with the Beetle finished and the Audi holding fast as a daily driver Blair was in a position to start a new personal project.

For about as long as I’ve known him Blair has had this 1933 Dodge Sedan body. In 2013 a loose inspirational sketch was drawn, a frame was started, the body chopped and a motor purchased before the car and its components became an almost permanent fixture in the corner of his shop.

Recently Blair pushed the project back to the center, this time with the intent that it wouldn’t wind up back in the corner.

Always a fan of a good deadline Blair picked this 2016’s Motorama Custom Car & Motorsports Expo as the venue to début the car. A show that is a mere three and change months away.

He won’t be tackling a build of this magnitude on his own his dad –who is pretty darn handy around the shop in his own right– and a number of wrench turning friends like myself will be lending a hand along the way to ensure this car makes it to the International Centre floor March 11-13.

The lion’s share of the work however still sits with Blair and he’s been quickly making significant progress.

The stock floor was cut out and left on the dolly so that the body could be channelled over the new frame because this car, like most of Blair’s others, is going to find itself sitting directly on the ground when parked.

The frame now has a four-link tacked in the rear and the plan up front is to use a straight axle. Initially only the rear was going to be bagged but as of now the front will also use air suspension.

Blair has also got a few ideas in mind for the front suspension components that will make it really slick when finished, but there will more on that in a later update.

For power the car will be using a 324 cubic-inch Oldsmobile Rocket motor, a motor that has proven plenty effective in many a hot rod. But Blair isn’t really shooting for ‘plenty effective’ with this build, he’s shooting for downright ridiculous and down right ridiculous meant forced induction.

However not just any turbo set up would do, no this build called for a supercharger that would be visible from the driver’s seat and be the focal point of the front end.

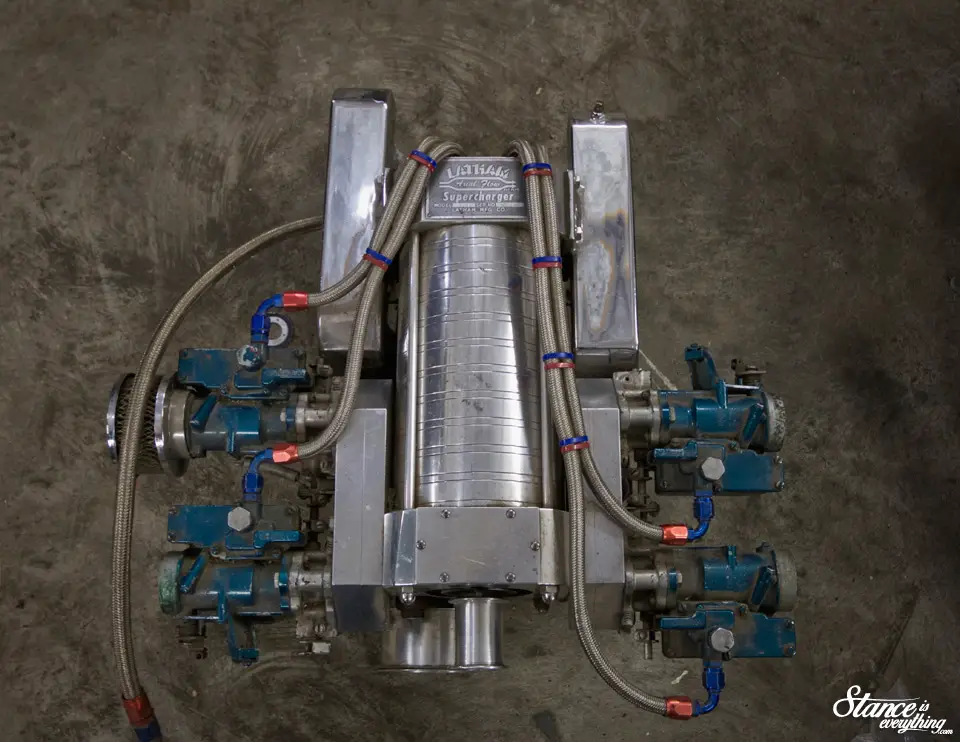

And on that note not just any ‘charger would do either, for this build forced induction will come by way of a Latham Axial Flow Super charger.

A what you say?

A Lataham, an extremely rare unit of which the first generation Florida produced versions number in less than a 600. It’s the only one I’ve ever seen, and likely the only one I’ll see for some time.

They are known for both their unique sound in operation and unique look when sitting idle thanks to the quad Carter carburetors hanging off the side.

Hard to find today this one, despite not being pictured full trimmed, has all the necessary components to make it work, something that can’t be said about the few on the market today.

The combination of motor and super will be mated to a two-speed Powerglide transmission terminating into a Ford Mustang GT rear end.

The works should be good for around 600hp to the wheels, which combined with the line locks Blair has deemed mandatory will result in ample tire smoke at the press of the skinny pedal.

But there’s still much to go before that motor barks and that progress will be documented here as I hang around the shop lending a hand when I can and staying out-of-the-way when I can’t.

Motorama or bust, here we go.

Very cool build, the supercharger alone makes it stand out already, no doubt there will be a lot of custom fabrication and suspension work to make it stand out even more.

awesome supercharger. If it’s setup like my brief googling leads me to believe a very careful inspection that the rotor tip and stator tip (non moving blades) clearances are good and that the bearings have zero play. For this style of compressor to be efficient, it relies on very tight rotor tip to case and stator tip to rotor shaft clearances. May be worth making friends with or calling on that aircraft mechanic friend to give it a look.

Odd setup for a automotive engine since they can’t benefit from the HUGE pressure ratios that this style of compressor can generate…500+psi on modern jet engines! How many stages / rotors does it have?

also make sure that the rotor is balanced! Look at any youtube of fan blade out testing on a jet engine to see what an unbalanced rotor can do. Realistically it won’t be that drastic of the rotor is imbalanced since it doesn’t have massive blades, but it could trash the supercharger in a hurry.

I can’t wait to see this build transform!