On the fly adjustable suspension has come a long way since the days of yore. Companies like Air Lift make kits (or at the very least can provide a starting point) for a wide variety of cars and if hydraulics are more your fancy institutions like Hydroholics are capable of doing the same.

The need to repurpose old air plane systems, semi truck equipment, or any sort of other retro fit no longer really exists. However that doesn’t mean people are still not going to retroifit things for the sake of a good challenge.

About a month ago I spotted this car on the Stance|Works forums and noticed immediately that the air management looked unlike anything else I’d ever seen before.

I then promptly forgot about it until I started looking through the owners build thread earlier this week.

A mechanical engineer by day, and car modifier by night, the owner of this car used parts he acquired from various job sites to build his system. The guts of the management are built around pilot operated check valves and an assortment of valve banks.

Since I would probably just mistype explaining it out so here is an abridged breakdown from the owner:

I had an idea to use what we call PO checks, (pilot operated check valves), they are very reliable and we actually use them for safety applications so if air is removed from the retract of a heavy tool the cylinder will not drift.

Sounds perfect for holding air in an air bag.

When you want to to deflate you just supply a pilot air signal to reverse the check valve. I scavenged 4 of the best I could find and gathered up some parts from old valve banks that would control the air to the PO checks.

Then I scored some old R134 tanks that quickly became my 8 gallons of air tanks.

This is all installed in a fittingly unique Mercury Grand Marquis and factory air springs were put to use in the rear and up front more conventional after market bags are used in modified control arms.

The sum of all these parts is what you see below and the build thread is on going on Stance|Works.

Curiously enough he is also from Ontario. Awesome.

Site Updates

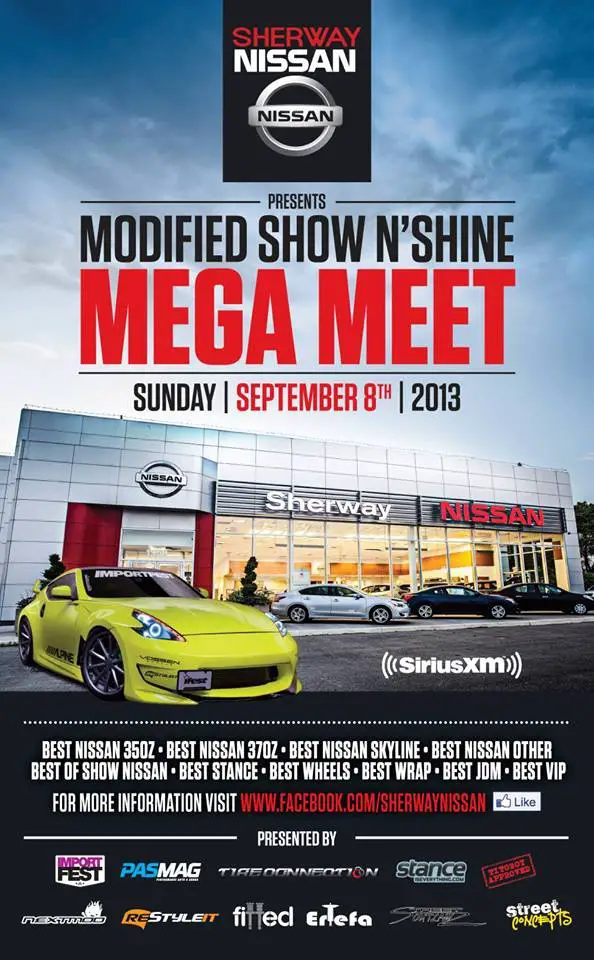

Sunday I will be at Sherway Nissan MegaMeet presented by Importtfest. I should have a booth with some merchandise for sale so come on by.

Flashback Friday

Even though the set-up above is pretty rad this is still one of the coolest I have ever seen. From the when tanks explode WTF Friday .

spool valve = problems

^ Reliability issues?

yes sir , spool valves used to be the ‘go to’ but prove to be the least reliable due to all the rubber o rings inside along the spool. waaaay to many moving parts for the long term. great for perfectly clean and filtered service in industry.

diaphram valves are the ONLY choice for years of trouble free service.they are designed to be used with water / oil / air , they can handle the often dirty and or condensation filled compressed air that is present in automotive apps.

Good to know. Not that I would have gone with something off the wall like this.